First Stage Drive Belt Replacement

About

This procedure provides instruction to remove and install the First Stage Drive Belt.

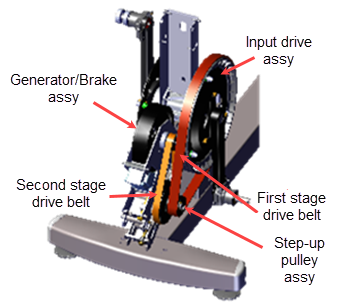

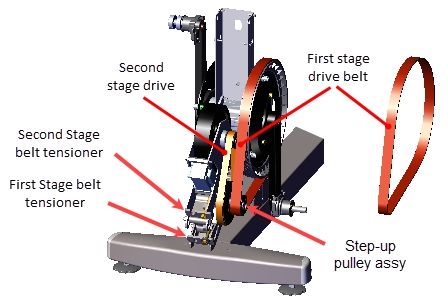

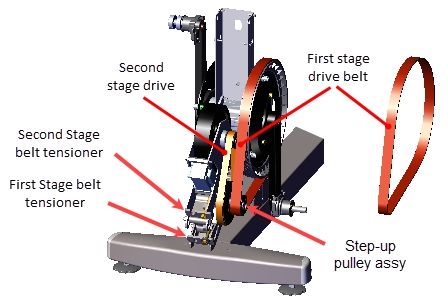

A Two Stage Input Drive system utilize a two stage drive belt system, a first stage drive belt and second stage drive belt, that uses a Step-up Pulley/Tensioner assembly to connect the input drive assembly to the generator/brake assembly. Always adjust the first stage drive belt first and then the second stage drive belt.

Specifications

| System Component | Specification |

|---|---|

| First Stage Belt Drive Tension - New(1) | 140-150 lbs (63.5 - 68 kgs) |

| First Stage Belt Drive Tension - Used(1) | 125 - 135 lbs (56.7 - 61 Kgs) |

| Drive Component Assy Carriage Bolts | 110-120 lbs (50- 54.4 kgs) |

| (1) New belt tension applies to new belt first time installations. Used belt tension applies to reinstalling an existing belt or when re-tensioning an existing used belt. | |

Procedure

Review entire procedure before starting.

Removal Instructions

- Remove the Drive Access panel, see Drive Access Panel Replacement.

- Remove the right and left Drive Disk coves, see Drive Disk Covers Replacement.

- Remove the right Stairarm, see Stairarm Replacement.

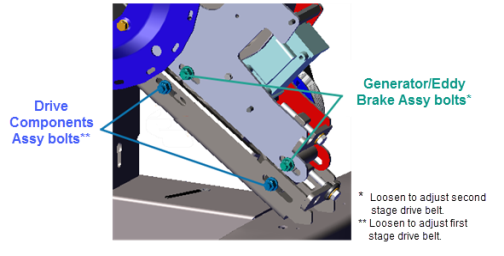

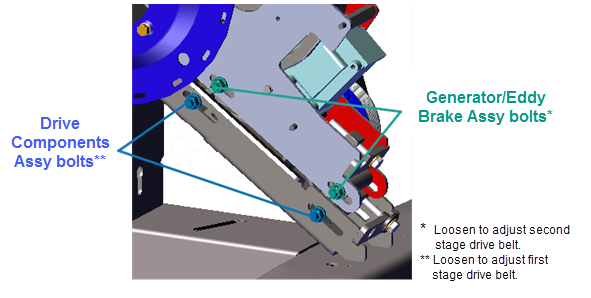

- Use a 1/2" socket to loosen the two Drive Components assembly carriage bolt nuts (left side) just enough to allow movement. Do not remove the fastener nuts.

- Use a 1/2" socket to loosen first stage belt tensioner and walk the first stage drive belt off the input drive and smaller Step-up Pulley/Tensioner assembly pulleys. Remove the first stage drive belt.

Installation Instructions

- Install the first stage drive belt by walking the belt onto the Input drive and the smaller first stage Step-up Pulley/Tensioner assembly pulleys. Adjust the First Stage Tensioner enough to hold the tensioner and belt in place. Rotate the crank and make sure that the belt is properly aligned and seated in the pulley grooves.

- Adjust the first stage drive belt tension to specification, see First Stage Drive Belt Tension Adjustment.

- Use a 1/2" socket to fully tighten the two Drive Components assembly bolts. TorqueTorque is a measure of the force that can cause an object to rotate about an axis. Bolt/nut example: 5 nM torque is equivalent to 5 newtons of force applied one meter from the center of the bolt, 6 ft-lb is equivalent to 6 lb of force applied 1 foot away from the center of the bolt. bolts to 180 in-lbs +/- 54 (20.3 +/_ 4.5 Nm).

- Verify that the second stage drive belt is within the specified tension, see Second Stage Drive Belt Tension Adjustment. Retention the belt if not within specification.

- Reinstall the right Stairarm, see Stairarm Replacement.

- Reinstall the right and left Drive Disk coves, see Drive Disk Covers Replacement.

- Reinstall the Drive Access panel, see Drive Access Panel Replacement.

- Verify machine operation and return to service, see Operation Verification.