Brake Caliper Assembly Replacement

About

This procedure provides instruction to remove and install the Brake Caliper assembly. There are separate replacement procedures, one for the Spinner® ChronoSpinner® Chrono™ Power bike.™ Power and one for the Spinner® Climb™ models.

Brake Caliper replacement requires removal of the flywheel, drive belt, and generator belt.

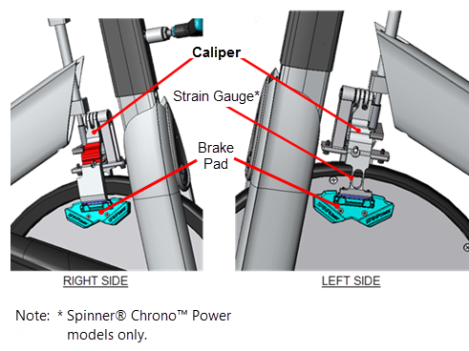

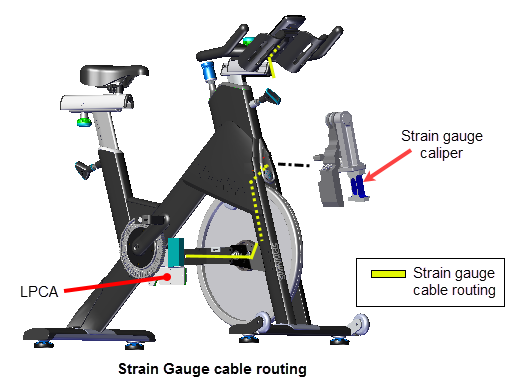

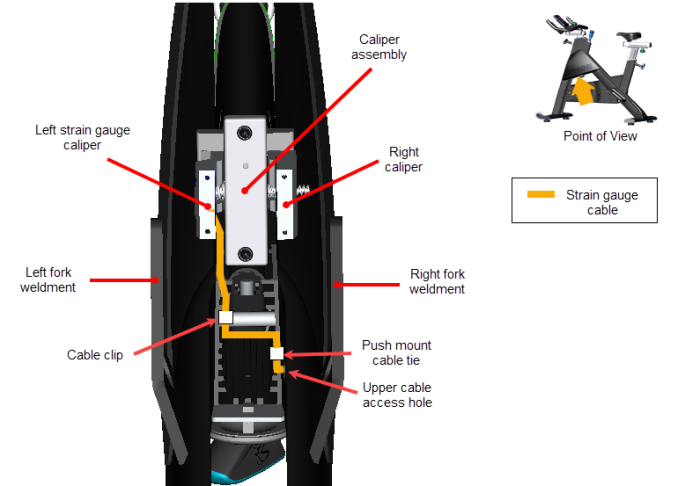

Strain gauge cable routing

(Spinner® Chrono™ Power models only)

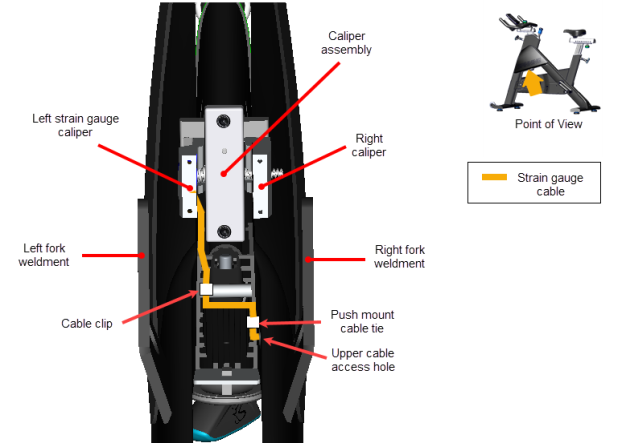

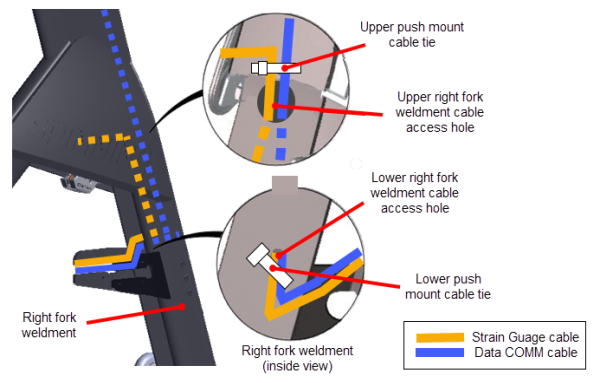

Beginning from the strain gauge left side caliper, the cable crosses to the right side and enters the right fork weldment upper cable access hole. From there the cable travels down the right fork weldment exiting at the lower cable access hole traveling across the cross member connecting to the LPCALower printed circuit assembly; generally this refers to the lower board. On treadmills, this is the motor controller unit (MCU), and on self-powered units, it is the main board in the lower section. board strain gauge input connector.

Specialized Tools

| Tool | Part Number | Qty | |

|---|---|---|---|

| Magnetic Gap Fixture kit* |

|

PPP000000058248101 | 1* |

| Cable Puller (fish tape)** |

|

General purpose** | 2 |

|

Note: * Each Magnetic Gap Fixture kit contains two (2x) Magnetic Gap Fixture tools. |

|||

Parts

| QTY | Part Number | Description | Image |

|---|---|---|---|

| 2 | PPP00RX2809393M000 | Push Mount Cable Tie |

|

| 4 | General purpose | Cable Zip Tie (6 - 8 in) |

|

| 1 | PPP00RX10L93XSX000(1) | Self-Adhesive Cable Clip |

|

| Notes: (1) Only needed if the cable clip is loose, damaged, or missing. | |||

Procedure

Replacement Procedures

- Spinner® Chrono™ Power models

Replacement Procedure - (Spinner® Chrono™ Power models only)

Review entire procedure before starting.

Removal

- Remove front and rear belt guard covers, see Belt Guard Cover Replacement.

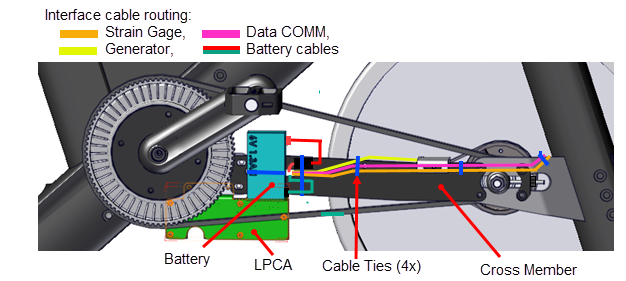

- Cut the four cross member cable-ties (4x) that secure the strain gauge cable to the cross member. Discard the cable ties.

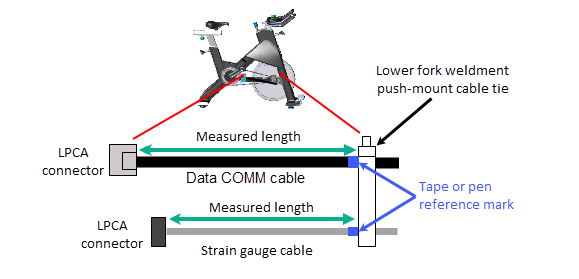

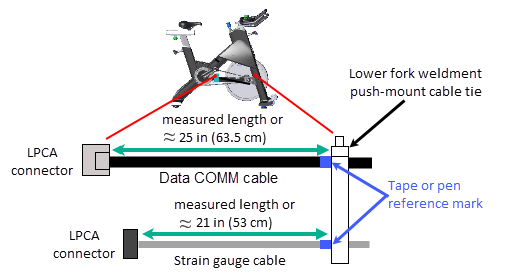

- Disconnect the Data COMM, Strain Gauge, Battery, and Generator cables. Use a pen or tape to mark the Data COM and Strain Gauge cables at the lower fork push mount cable tie.

|

|

Note: Alternatively you can measure and record the Data COMM cable and Strain Gauge cable lengths from the LPCA connectors to the right fork lower push-mount cable tie. The reference marks (or measured cable lengths) will be used during the installation process. |

- Remove the flywheel, see Drive Belt, Generator Belt, and Flywheel Replacement.

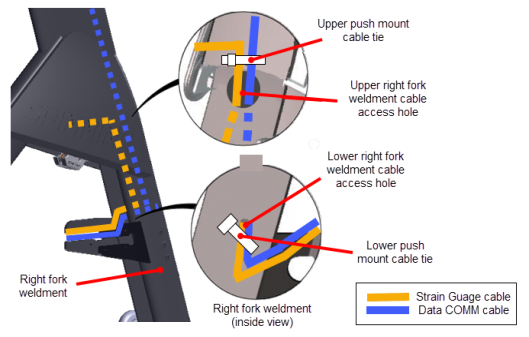

- Carefully cut and remove the upper and lower push mount cable ties (2x) that secure the strain gauge and Data Comm cables to the inside of the right fork frame weldment. Discard the push mount cable ties.

- Remove the strain gauge cable from the cable clip located on the upper left fork frame weldment (next to the left caliper).

- Remove the strain gauge cable from the inside of the right fork frame weldment.

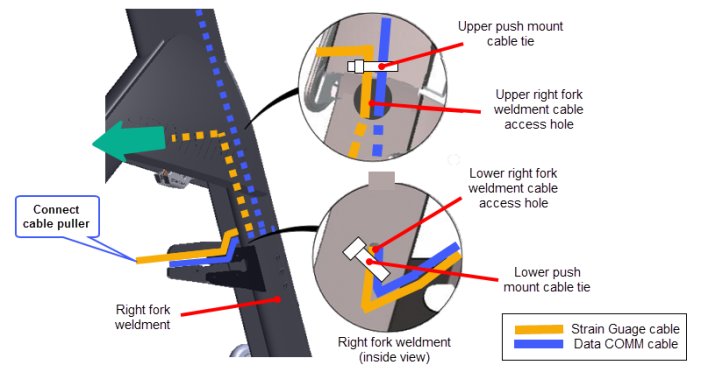

- Attach a cable puller (or fish tape) to the strain gauge cable LPCA connector.

- Then grasp the strain gauge cable (and attached cable puller) at the right fork weldment upper cable access hole and gently pull the cable from the inside of the right fork weldment. Stop pulling when the cable puller exits the upper cable access hole. Disconnect the cable puller from the strain gauge cable leaving the cable puller inside the right fork weldment. The cable puller will be used to reinstall the strain gauge cable.

|

|

IMPORTANT: Attach a cable puller (or fish tape) to the LPCA connector end of the strain gauge cable before removing from the inside of the fork frame weldment. The cable puller will be used to reinstall the cable through the frame. |

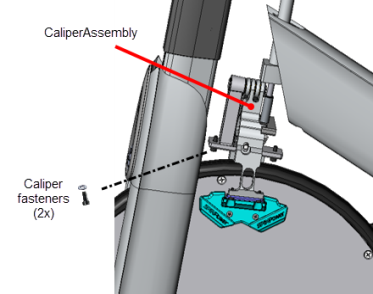

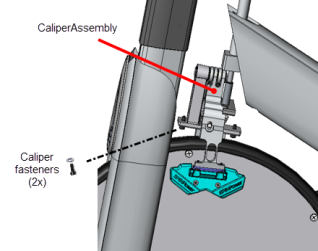

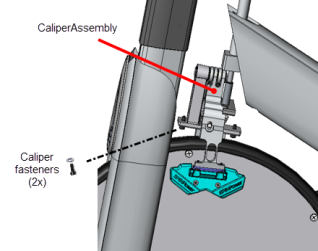

- Remove the two 4 mm hex key bolts (2x) and washers (2x) that secure the caliper assemble to the frame and remove. Hold the caliper assembly while removing to prevent it from falling to the floor causing damage. Retain part(s) and/or fastener(s) for installation.

Installation

- Install the brake caliper assembly :

- Install the caliper assembly so that the strain gauge is located on the left side of the frame. Align the two mounting bolt holes and attach using the two previously removed 4 mm hex key bolts (2x) and washers (2x). Loosely tighten the fasteners.

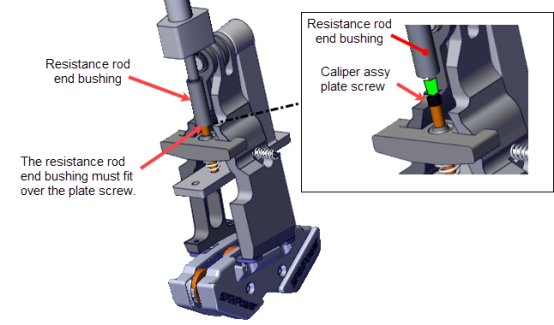

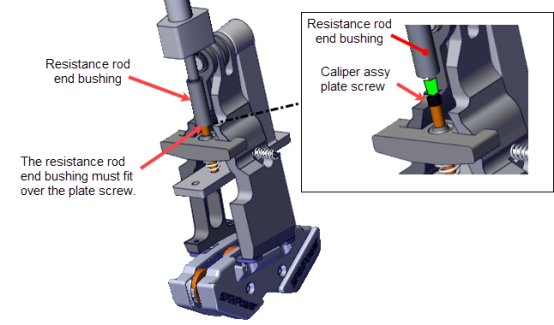

- Make sure that the resistance rod end bushing is seated over the caliper assembly plate screw and then fully tighten the two (2x) fasteners.

|

|

Note: Make sure that the resistance knob rod end bushing is seated over the caliper plate screw. |

- Reinstall the strain gauge cable downward through the inside of the right fork weldment:

- Attach the strain gauge cable - LPCA connector to the previously installed cable puller exiting from the upper fork weldment cable access hole.

- Grasp the cable puller exiting from the right fork lower cable access hole and pull the strain gauge cable downward through the inside of the right fork frame weldment. Leave slack in the cable, do not pull the cable tight. Remove the cable puller from the cable.

- Insert the strain gauge cable into the self-adhesive cable clip located next to the left caliper magnetic sensor.

- If the selt-adhesive cable clip (PPP00RX10L93XSX000) is loose or missing, replace as follows:

Remove the existing self-adhesive cable clip.

- Remove any residue adhesive using a clean rag and Isopropyl alcohol cleaning solvent.

Reinstall a new self-adhesive cable clip (PPP00RX10L93XSX000).

- If the selt-adhesive cable clip (PPP00RX10L93XSX000) is loose or missing, replace as follows:

- Secure the Data COMM and strain gauge cables to the fork weldment lower and upper push-mount cable ties: Secure the cables to the lower push-pin first and then the upper push-pin cable tie.

- Install new upper and lower right fork weldment push‑mount cable ties (2x); one next to the upper right fork weldment cable access hole and one next to the lower right fork weldment cable access hole.

- Secure the Data COMM cable and Strain Gauge cables to the right fork weldment lower push-mount cable tie:

- Place the Data COMM cable and Strain Gauge cable into the right fork lower push-pin cable tie. Adjust each cable to the prior marked lower push-pin reference mark (tape or pen) and tighten the cable tie.

- Alternatively, adjust the Data COMM and Strain Gauge cable lengths to the prior measured length from the LPCA cable connectors to the lower push mount cable tie and then tighten the cable tie. If you did not make these measurements, adjust the Data COMM cable length to approx. 25 in (63.5 cm) and the Strain Gauge cable length to approx. 21 in (53 cm) and then tighten the cable tie.

- Secure the Data COMM cable and Strain Gauge cables to the right fork weldment upper push-mount cable tie at the following conditions:

- Strain Gauge cable: Adjust the Strain Gauge cable so that there is a small amount of slack from the left caliper cable clip across the frame to the right side upper push-mount cable tie.

- Data COMM cable: Pull the Data COMM cable upward thru the upper fork weldment cable access hole until snug. Then secure the cable so that the cable slack will NOT touch or rub against the top of the fly wheel.

- When both cables are set to the install conditions, tighten the upper push-pin cable tie.

.

- Reinstall the flywheel, see Drive Belt, Generator Belt, and Flywheel Replacement.

- Hand rotate the pedals and verify that the Data COMM cable does NOT touch or rub against the top of the flywheel.

- If the cable rubs against the flywheel, the Data COMM cable slack must be readjusted so that the cable does not touch the flywheel. This may require removing the flywheel to make adjustments.

|

|

CAUTION: Rubbing against the top of the flywheel will damage the Data COMM cable. Make sure that the Data COMM cable does not touch the top of the flywheel and is securely attached to the upper push-pin cable tie. Remove slack as necessary. |

- Ride the bike and verify that the console powers on and is operating normally.

- Make sure the WATTS, RPM, TIME, DISTANCE, and INTERVAL metrics are reporting correct information.

- Access the service mode and review the ERROR LOG, see Error Log. Make sure there are no current logged error code 30s "Communication issue with the LPCA".

- Replace the front and rear belt guard covers, see Belt Guard Cover Replacement

- Verify the bike operation per Operation Verification Checklist and return to service.

Replacement Procedure -

Review entire procedure before starting.

Removal

- Remove front and rear belt guard covers, see Belt Guard Cover Replacement.

- Remove the flywheel, see Drive Belt, Generator Belt, and Flywheel Replacement.

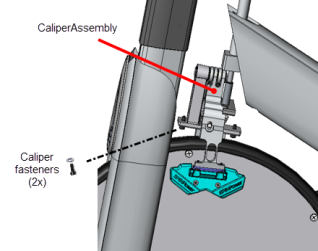

- Remove the two 4 mm hex key bolts (2x) and washers (2x) that secure the caliper assemble to the frame and remove the caliper. Hold the brake caliper assembly while removing to prevent it from falling to the floor causing damage. Retain part(s) and/or fastener(s) for installation.

Installation

- Install the brake caliper assembly :

- :Position the brake caliper assembly onto the frame weldment mounting bolts and secure using the two previously removed 4 mm hex key bolts (2x) and washers (2x). For Spinner® Chrono™ Power models, install the caliper assembly so that the strain gauge is located on the left side of the frame.

- Make sure that the resistance rod end bushing is seated over the caliper assembly plate screw and fully tighten the fasteners.

|

|

Note: Make sure that the resistance knob rod end bushing is seated over the caliper plate screw. |

- Reinstall the flywheel, see Drive Belt, Generator Belt, and Flywheel Replacement.

- Replace the front and rear belt guard covers, see Belt Guard Cover Replacement

- Verify the bike operation per Operation Verification Checklist and return to service.

See Also